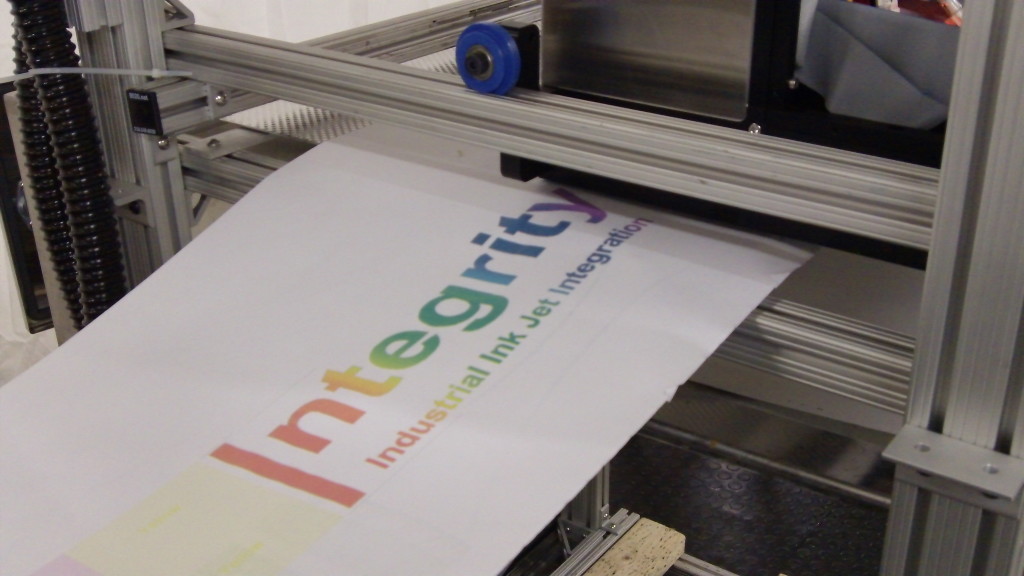

Inkjet printing of industrial graphics for labels, flexible packaging, and direct to product has been increasing rapidly as manufacturers recognize the many benefits of digital printing:

- Just-in-time printing for efficient inventory management on-site and for customers

- Low capital cost compared to a digital press

- Low cost of ownership – Rapid ROI

- Improved uptime/efficiency – reduced downtime

- Significantly reduced set up time for new jobs/artwork

- Increased agility and print job flexibility

- Lower overall cost per print

However, industrial applications are often challenging to meet, therefore, each application needs to be evaluated and developed on its own merits. The Inkjet Experts at Integrity works with you to ensure successful implementation and engineering team carefully considers a wide range of factors including:

- Cost and Economics (fluids, system hardware, process gains, production losses, personnel)

- Technology (inks, printheads, resolution and image quality, speed, reliability)

- Process optimization (pre-treat, post treat, dry/cure)

- Work flow (fixed date, variable data, streaming data, interface to existing line control)

- Product motion and control (is the current production line adequate?)

- Print system tending and storage protocols

Integrity provides a mix of consulting and engineering services to work with clients to help determine if an inkjet process solution is appropriate, and assisting with a phased evaluation and implementation program.