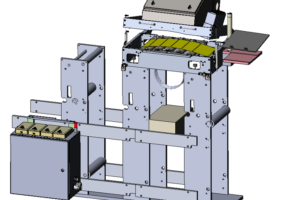

Versatile and Scalable Inkjet System Controller that allows you to explore different inkjet printhead technologies. The Universal Print Controller is powerful enough to move with your development cycle, from R&D to a full industrial integration.

Integrity’s Universal Inkjet Print Controller can be configured to drive up to 8 printheads from multiple vendors such as Dimatix, Xaar, Kyocera, Toshiba Tec and Konica Minolta.

Universal inkjet print controller features

- Drives up to 8 printheads

- Compatible with Dimatix, Kyocera, Ricoh, Toshiba Tec, Konica Minolta, Xaar, Xerox, etc.

- Expandable for multi-head solutions supporting multiple fluids

- Usable for every stage of your program, from feasibility through production

- Stand alone use or integrated with conveyors, X-Y tables, and production ready systems

- Robust industrial connectors

The universal print controller is aggressively priced as part of a development package designed to take you from feasibility to development to production, making the most of your investment during every phase of your process development cycle.

The base unit includes the ability to drive one head, with licenses available for additional heads as needed. Printhead configuration is user changeable.

Contact Integrity today to discuss your application needs with our engineering team.

Custom Digital Hybrid Label Press

The versatility of digital printing customized to meet your business and resource needs.

In today’s fast paced, highly customized and personalized world, the business of label and package printing is being transformed. Rise to meet market demands by retrofitting existing equipment with high resolution inkjet to create a versatile hybrid that integrates the best features of analog and digital printing.

The Power of Hybrid Systems

- Convert existing presses to gain the flexibility and versatility of inkjet

- Unparalleled printing versatility at a fraction of the cost

- Reliable inkjet systems tailored to application requirements

Integrity Works With You To

- Determine application specifications and interface requirements

- Integrate Integrity’s robust core modular components to perform flawlessly on any press

- Judiciously select inks for optimized ink / substrate performance and unparalleled image quality

Economic Advantages

- Significantly reduced set up time allows just-in-time printing for efficient inventory management

- Low capital, low cost of ownership, improved uptime/ efficiency – reduced downtime

- Increased agility and label/packaging flexibility

Contact Integrity today to discuss your application needs with our engineering team.

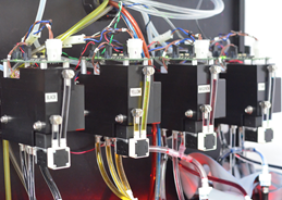

Ink Management Systems

Integrity understands the importance of fluid management in inkjet systems which is why we offer an Ink Delivery module and a Recirculating Reservoir that can be used independently or together.

The Ink Delivery module is designed to be used with a variety of fluids and is tailored to deliver ink at the proper rate based on usage by the choice of pump.

For fluid management closer to the jetting mechanism, Integrity’s Recirculating Reservoir is ideal, providing constant fluid circulation through the printhead, reservoir chamber, and an in-line degassing unit. This combination assures your fluid is always at the ready for optimum performance.

Ink Delivery System

- Delivers Aqueous, Solvent, UV Curable, and Oil based fluids to on-head reservoirs

- Supports up to four heads with four different fluids

- Pump mechanism can be varied depending on required flow rate

- Compatible with most ink supply designs

Recirculating Reservoir

- Recirculating circuit for even temperature and particulate management

- Integrated continuous-pass degassing unit

- Provides management of Aqueous, Solvent, UV Curable, and Oil based fluids

Contact Integrity today to discuss your application needs with our engineering team.